The IBA Conference

One more from 2025

Researcher Jessica McConnell attended the IBA conference back in November, and as a gentle January starter we’ve got her to paint us a picture of the research landscape as seen from that conference.

The annual international battery materials association (IBA) conference was held at the end of 2025 from Nov 9th – 14th. The event was hosted by The National University of Singapore (NUS) in the Suntec Centre in Singapore. Gathered were global attendees who brought with them some of the most innovative research in the battery sector to date.

Throughout the five days, over 80 talks were shared and nearly 200 posters were presented. Even before the conference began, the itinerary pitched the tone by promising nearly half of the talks to focus on solid-state batteries (SSB) or sodium batteries. Considering the number of electric vehicle (EV) manufacturers (Chinese manufacturers especially) announcing their upcoming plans for commercialising SSB EVs, this focus comes as no surprise.

One talk on practical applications for SSBs by Hong Li from the Institute of Physics, Chinese Academy of Sciences stuck out to me. He spoke on improving interfacial contact in these batteries by means of in-situ solidification of the electrolytes but, like anything, this comes with its own challenge of incomplete solidification. Hong Li also highlighted that current SSBs in or coming to the market are hybrid solid liquid electrolyte batteries (HSLBs) which often still require some liquid electrolyte injection. However, SSBs with no liquid at all aren’t far behind with the EV market expecting them in the next few years.12

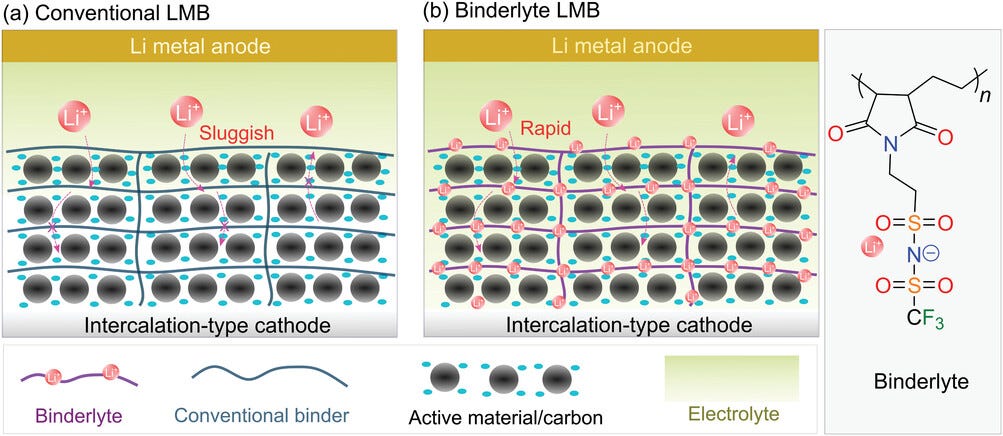

One talk revisited aqueous batteries by Yi Cui from Stanford University, delving into their ongoing work on Metal-H2 batteries by studying derivatives of the long appreciated Ni-H2 batteries.3 The Cui group seeks to find an alternative to the high cost Ni-H2 systems by pursuing alternative metals to Ni; Mn being highly attractive. This wasn’t the only talk returning to widely used battery materials to improve upon. Michel Armand from CIC Energigune spoke on the polymer electrolyte they have been developing which can also be used as a binder in the cathode, it’s being named “binderlyte”.4 They have used it as an alternative to poly(vinylidene fluoride) (PVDF) binder, the current standard for NMC cathodes, and in their studies it notably outperforms PVDF at high charge rates. The “binderlyte” not only acts as binder but allows for the transport number inside the electrode to increase to unity in between particles.

Taking the scale smaller, Jürgen Janek from University of Geissen presented on Li grain boundary sizes in Li metal for anodes.5 Smaller grain sizes are more favourable as they allow for better ion transport. Janek’s team observed that by depositing a metal interlayer (in their study gold or silver were most discussed) on the current collector, the lithium grains form smaller and more preferentially orientated for transport. While monitoring the grain sizes of lithium metal as it was plated and stripped from the pristine titanium current collector, they saw that the large grains were reversibly formed and would shrink during the Li stripping. It was also observed that the gold and silver interlayers appeared to suppress this reversibility, keeping the formation of lithium more consistent at all points of cycling.

Prof. Jeff Dahn from Dalhousie University gave a fantastic presentation on his work on LFP cathode degradation, contextualised through rickshaws used in warmer regions. He focussed the talk on the irreversible degradation that high temperature working conditions (>40 °C) inflict on the LFP cathode; measurably increasing the charge transfer resistance. He showed that the degradation is subject to the cumulative time the battery spends at high temperatures, not one event. He also teased of a new additive “X” that his group has been using to seemingly fix the issue of high charge transfer resistance and temperature degradation. This additive considerably extends the lifetime of the batteries. All the conference were left in anticipation for the reveal of additive X, hoping that it comes sooner rather than later.

Sadly, it might be later as the next IBA conference will be in Spain in 2027, a longer wait than usual, as it returns to springtime after modifications made during pandemic times. The conference this year has retained its high calibre reputation, and recognition for this goes to Prof. Shirley Meng, the IBA president, and the organizers Assoc. Prof. Balaya Palani and Dr. Derrick Fam. Their hospitality, and that of Singapore, was flawless. As an early career academic, I loved seeing many of the big names in batteries present to and question each other. Great minds in healthy debate made for enthralling entertainment.

🌞 Thanks for reading!

📧 For tips, feedback, or inquiries - reach out

📣 For newsletter sponsorships - click here

🌐 Follow us on Twitter, LinkedIn, and our website

All Current And Upcoming EVs With Solid-State Batteries, https://insideevs.com/news/771402/every-solid-state-battery-ev/ , (accessed 9 January 2026).

‘Production-Ready’ Solid-State Battery Promises 5-Minute EV Charging, https://www.forbes.com/sites/jimgorzelany/2026/01/07/production-ready-solid-state-battery-promises-five-minute-ev-charging/ , (accessed 9 January 2026).

J. J. Smithrick and P. M. O’donnell, Nickel Hydrogen Batteries An Overview, Reno, Nevada, 1995.

A. Santiago, E. Sanchez-Diez, U. Oteo, I. Aldalur, M. Echeverría, M. Armand, M. Martinez-Ibañez and H. Zhang, Small, DOI:10.1002/SMLL.202202027.

J. Becker, L. Schuster, S. Kremer, T. Fuchs and J. Janek, DOI:10.26434/CHEMRXIV-2025-371ZL.

Brilliant recap of what sounds like a really solid conference lineup. The bit about Jeff Dahn's additive X for fixing LFP degradation in high temps caught my attention because we've been working on similar thermal management challenges in tropical climates where batteries just cook. The way he connected it to rickshaw applications is actually genius because those vehicles are probably the most brutal real-world test bed you could ask for, constant cycling inextreme heat. Curious if the interlayer approach for lithium grain control will actualy scale though, depositing gold seems pricey even if it works well.

Thanks. Great resource! Very useful