Deep dive in hybrid battery packs

On October 24, 2024, CATL launched the Freevoy Super Hybrid Battery, which is an interesting concept: it’s hybrid in two ways. First, it’s for hybrid vehicles (plug-in hybrids for example) so it’s a relatively small battery compared to pure EV batteries, and it’s also a hybrid battery pack, in the sense that it mixes cells of two different chemistries.

Gaël takes us through what he can deduce1 from the press release, with the help of OCV curves measured at CSEM.

Mixing different chemistries

The concept in and on itself is not brand new. Back in 2021, CATL announced its AB hybrid battery pack to mix sodium-ion cells with lithium ion cells (chemistry undisclosed but probably LFP) and NIO announced its mixed NMC/LFP battery pack, likely based on the same technology and concept.

The concept seems to belong to this family of patents filed by CATL between 2020 and 2022:

The present application relates to a battery module including a first-type battery cell and a second-type battery cell at least connected in series, where the first-type battery cell and the second-type battery cell are battery cells of different chemical system.

In the patent from 2021 we can read that it applies to any batteries of type 1 and 2 of capacity C1 and C2 respectively, where it is recommended to use chemistries of type NMC, NCA or LMO as type 1 and LFP or LVP as type 2.

But… why?

The first question that would spring to mind is maybe… why mix chemistries together? A few articles like Nigel Taylor’s summary over at Batterydesign.net have done a very good job at summarizing the advantages outlined in the press release, so we figured we’d explain a bit more in-depth where the claims could be coming from.

SoC accuracy

The first thing we can notice about type 2 cells (LFP or LVP) is that their OCV presents plateaux, whereas type 1 cells (including sodium-ion) have rather linear OCV curves:

The linear OCV curve of LFP, coupled with its hysteresis (the gap between the orange and blue curves on Figure 1) make it challenging to estimate the SoC of LFP cells, often with accuracy between 6-10%. Sodium-ion and NMC cells, on the other hand, have much more linear OCV curves with low hysteresis, so their SoC accuracy is generally around 3%.

What would happen if we put LFP and NMC cells (of the same capacity) in series? Well, we could basically sum their OCV curves:

We can see that the sum of the OCVs is rather linear, thanks to the contribution of the NMC cell, so the SoC is easier to compute, overcoming the limitation of the type 2 cell. Hence this part of the press release:

CATL takes the sodium-ion battery [the type 1 cell] as a SOC benchmark for monitoring of the AB battery system to assist in calibrating the lithium-ion battery's [the type 2 cell so probably LFP] charge level. This elevates system control precision by 30%, adding over 10 kilometers to the pure electric range.

An interesting thing we can read in the patent is the fact that type 2 batteries are recommended to be oversized with respect to type 1 batteries.:

The Type 1 battery cells and the Type 2 battery cells satisfy the following criteria: 1.01×C1/C2≤N≤1.25, and C 1*<C2* ,where N is a battery charge balance rate of the Type 2 battery cells; and C1 and C2 are respectively capacities of the Type 1 battery cells and the Type 2 battery cells.

Since in series the same charge (in Ah) enters both batteries this means the type 2 battery will only be partially charged at most. In the NIO press release from 2021 we can also read:

The new hybrid-cell battery also has no battery modules as NIO applied its new-generation cell-to-pack (CTP) technology.

The Freevoy announcement has less details on this front but mentions:

the Freevoy combines sodium-ion batteries and lithium-ion batteries in a defined ratio and arrangement, with mixed, serial, and parallel connections

So I think what’s going on is that it’s not so much that their cells have different capacities (as in the patent), but rather that they make “super-cells” (each super-cell is actually N1 or N2 cells in parallels) which have different total capacity (capacities add up in parallel), as illustrated below:

(Note that capacity and cell numbers in the figure are totally arbitrary). This setup removes the need for the usual 14 cells in series making up a module, then modules being connected in parallel, hence the direct “cell-to-pack” design.

Low-temperature performance

Another important part of the press release is the following statement:

Addressing the inherent performance disparities between lithium-ion batteries and sodium-ion batteries at low temperatures, CATL has developed a full temperature range accurate BMS technology. This technology implements targeted zonal management for distinct chemical systems around the clock, effectively mitigating issues like inaccurate charge prediction or reduced power performance in harsh high and low temperature environments.

LFP batteries being known to exhibit high impedance at low temperatures, while it seems to be less the case with sodium-ion batteries, oversizing the LFP “super-cell” means that a lower current will pass through each individual cells (in parallel the current is spread across cells), so their internal resistance will be less impactful on the pack performance.

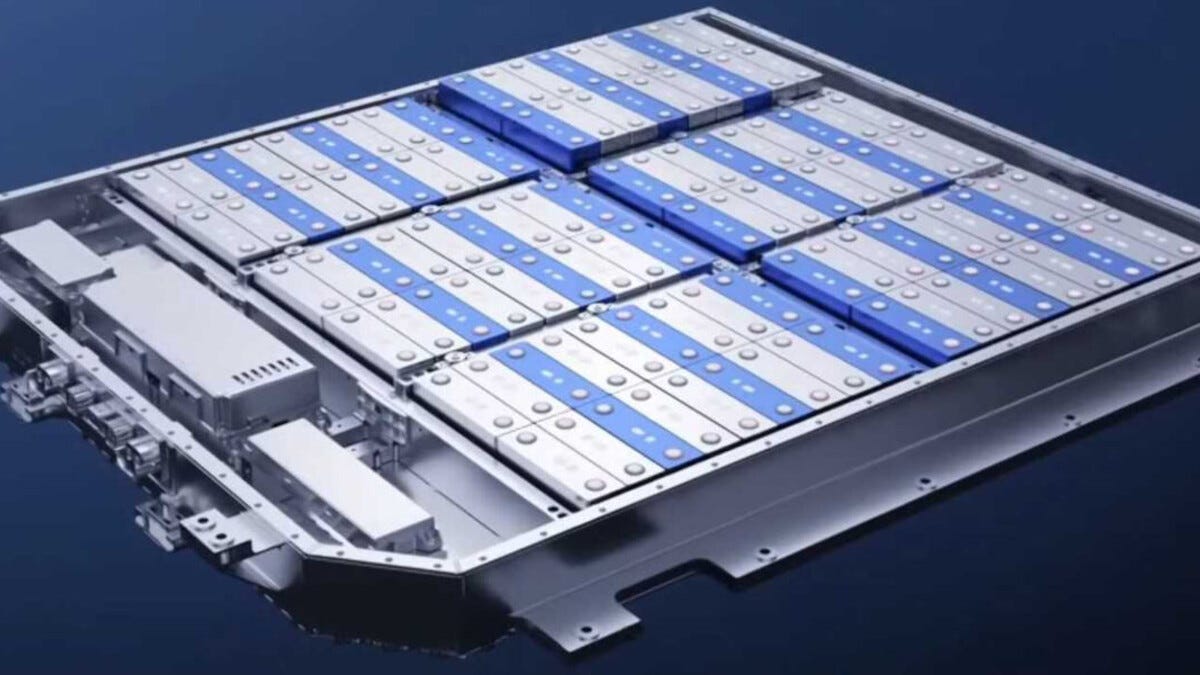

I guess that alternating spatially between type 1 and type 2 cells (as suggested by the picture below) also has some kind of effect on the spatial behaviour of thermal dissipation in the pack?

I could imagine that bulkier Sodium-ion batteries, in combination with slightly oversized LFP cells will tend to heat up less and perhaps more homogeneously than a regular LFP pack.

Fast charging

An interesting consequence of the oversized LFP “super-cell” is on fast charging, since the pack C-rate and cell C-rate end up being different.

That might be a little confusing, let me explain: on figure 3, I took the example of 8x80Ah NMC cells, in series with 10x80Ah LFP cells. In parallel, capacities add up so the NMC “super-cell” is 640Ah and the LFP “super-cell” is 800Ah. The “super-cells” are in series however, so they can only get the same amount of charge. The total effective capacity of the pack would then be 640 Ah ( limited by the capacity of the NMC cells). So, a fast-charge speed of 4C at the pack level would actually only correspond to an “apparent C-rate” of 3.2C for each of the 10 LFP cells, improving their fast-charging capabilities.

In addition, the bit on the LFP graphite anodes is interesting:

Furthermore, CATL has successfully applied its 4C ultra-fast charging technology in the Freevoy […] second-generation fast-charging graphite and […] multi-gradient layered electrode design.

We deep-dived into the Swiss startup Battrion and its layered graphite technology in 2022, it seems that CATL has upscaled a similar technology in its LFP cells (I assume their Na-ion still use hard carbon as the anode? So this would only apply to the LFP cells). This also probably boosts the fast charging abilities of the LFP cells, and contributes to reducing high-current, low-temperature losses.

What about drawbacks?

Since there is no free lunch, the drawbacks probably come in several forms. We could name state-of-charge imbalances and uneven aging of the different chemistries, but I don’t want to dive too deep into these topics since it would get a bit technical.

Cost increase

This may be the main reason why NIO ultimately backtracked on the hybrid packs. Over-sizing the type 2 cells means increased weight and cost at the pack level, since a portion of capacity is standing idle at all times. And yes, while SoC is easier to track with a few NMC cells in the pack, a smart algorithm is probably cheaper than idle capacity.

That being said, with CATL LFP cells trending below $70/kWh, wasting some capacity becomes less of a problem as time goes on. It might also be the reason why CATL cited hybrid vehicles as the main application, since pure range matters less than reliability in a battery pack that is intended to work in combination with a gas engine.

🌞 Thanks for reading!

📧 For tips, feedback, or inquiries - reach out

📣 For newsletter sponsorships - click here

🌐 Follow us on Twitter, LinkedIn, and our website

Since this is deduced from a press release, we can’t guarantee this to be 100% true.