Architectural Innovations in EV batteries : a tale of three press releases

by the ever brilliant Gaël

On March 18, BYD announced its Super e-Platform boasting an impressive 1 megawatt charging capacity, making charging speed on par with gas refueling.

The same day, CATL and NIO announced a partnership on battery swapping, aiming to, again, making EVs as fast to refuel as ICE cars by simply swapping the empty battery with a full one.

Just a day later, on March 19, Porsche Engineering revealed its intriguing 'AC battery' concept, which can use AC current directly to recharge, without needing an inverter.

These three press releases all imply some pretty cool innovations around EV battery architecture, albeit in pretty different ways, so I figured it’d make for a pretty interesting deep dive.

Today’s part 1 will focus on BYD and ultra-fast charging.

Part 1 : BYD

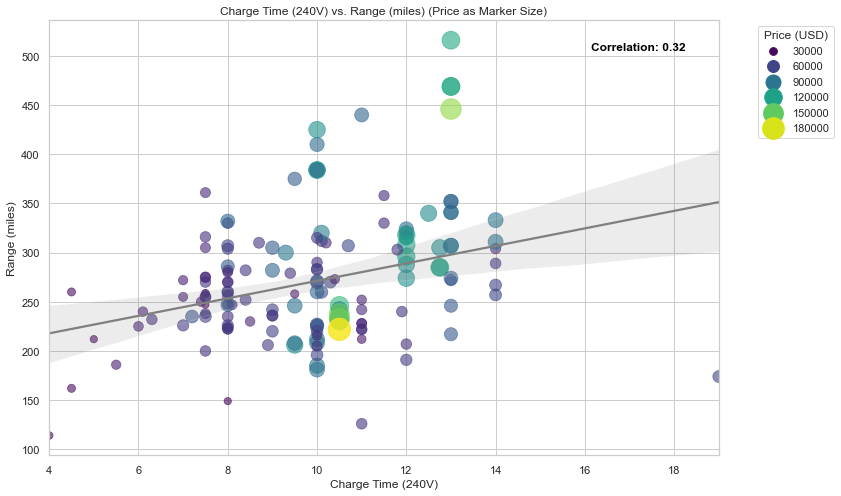

A recent article from Aionics Does battery performance determine electric vehicle cost? Unpacking the EV pricing puzzle has some really interesting graphs, including this one about the correlation between range and charging time, for a wide range of models:

The correlation is not too surprising : for a given charger (Level 2 charger 240V/48A or about 7kW) it takes more time to charge a bigger battery (in kWh) since charging time = energy / power.

The energy of the battery does not translate to range 1-to-1 though, because range is also affected by efficiency (in kWh/km) so EVs don’t always ‘Go The Extra Mile’ (as discussed by Kush a couple of months ago), hence the imperfect correlation.

I think what this graph really shows, though, is that range has improved — many EVs now comfortably clear the 250 miles range, and a good portion are above 300 miles — but charging speed has sort of become a bottleneck. Especially on highways.

What kind of current would be required to charge an 80 kWh battery in 10 minutes? Since Power = Energy / time, the charger should be able to deliver 80/(10/60) = 480kW of power. Since we also have Power = current x voltage, at 240V (typical plug) this translates to 2000A ! That would be completely unrealistic with the capabilities of most power electronics. Now, most cars have battery packs around 400V, so if the charger can go to that voltage, the current requirement drops to 1200A, which is better but still huge.

The Trend to Higher Voltages

That’s partly the reason why, in recent years, many carmakers have started transitioning from 400V to 800V electrical architectures (since voltages add up in series) — with the Porsche Taycan and Hyundai’s E-GMP platform among the early adopters. This trend is often accompanied by bold claims in press releases: one says “800V enables 2x faster charging,” another promises it will “resolve mileage anxiety.”

Let’s clear something up right away: voltage alone doesn’t increase range or charging speed.

Let's take the Porsche Taycan battery pack from batterydesign.net, and let’s look at two different wiring strategies:

Both have the same number of cells and the same energy rating of 105 kWh (so same range, assuming efficiency doesn’t change). But one has 99 in series and 4 in parallel, while the other has 198 cells in series and 2 in parallel. So the main thing that changes is the voltage : 400V vs. 800V.

To charge the Porsche Taycan (105kWh) in 10 minutes (1/6th of an hour), we’d need to deliver 630kW (105/(1/6)) of charging power. At 400V, we’d need 1575 amps (P=U*I) which is problematic: higher current means thicker and heavier cables, more complex cooling systems, and greater energy losses due to heat (since thermal losses increase with the square of the current). With an 800V system, you need about 788 amps, which is challenging but doable. So, by increasing voltage, automakers can reduce current for the same power level, leading to lighter, more efficient systems.

So while 800V doesn’t inherently give you faster charging or longer range, it enables higher power systems within the limits of what current components can handle — and that’s why we’re seeing more and more manufacturers going this route.

Now, with all that in mind, we can go deep on the press releases.

On to BYD press release

In the Super e-Platform press release, we can first read ‘a 30,511 RPM motor was developed, enhancing power density.’. Typical values are usually in the 10’000 - 15’000 RPM range so that’s a pretty high power motor, which allows for better acceleration. But enabling this kind of motor is the tricky part.

On to the main part : ‘BYD has developed full-domain 1000V high-voltage architecture, charging current of 1000A and a charging rate of 10C, fastest in the world ‘. From the BYD Tang L pack specs, the Blade Battery 2.0 specs and Woody Wu’s specs on LinkedIn we can try to work out how they reached these figures. Let's assume :

3.2V nominal voltage per cell

160 Wh/kg

10C charging rate (the press release says it’s cell level, but I suspect it might be system level, while the cells themselves are 8C, more on this below)

around 135Ah per cell

The first step is the pack voltage. We’d need a configuration of 313 cells in series to reach the 1000V in the press release. Given the likely energy density of their LFP cells, that seems pretty heavy so it’s possible the 1000V is a fully charged voltage and the actual, nominal voltage is a bit lower. We’ll assume 264 cells in series which give a nominal voltage around 850V (already pretty impressive).

The BYD blade batteries present the advantage of being high-capacity which allows a cell-to-pack design (all cells are in series, no need for modules with a few cells in parallel), so the pack is probably 264s1p.

That would put the total energy of the pack at 115 kWh, which is in line with the Tang L specs. If the cells can indeed take an 8C charging rate, at 135Ah that puts the charging current at 1080A (135/(1/8)), which matches the press release.

Finally, if the cells are slightly under-cycled to 108Ah (80% DoD, trading-off some range for charging speed), we can reach an apparent charging rate (at the pack level) of 10C, matching the press release. Alternatively, it’s possible that modifications to the electrodes/electrolyte (the ‘ultra-fast ion channels’) allow for a 10C charging at the cell level (if the cells are around 100Ah), but I haven’t seen this (yet) in any Blade 2.0 cell-level specs, and 8C is already impressive in and on itself for LFP!

Of course, this is supported by 1 MW chargers ‘The Megawatt Flash Charging enables the world's highest peak charging speed of "1 second for 2 kilometers", the Han L equipped with the Flash Charging Battery can achieve 400 kilometers of range with just 5 minutes of charging’.

Hence the main headlines following the press release like ‘BYD's New 'Megawatt' EV Charging Is So Fast It Makes Gas Irrelevant.’

On the front of ultra-fast chargers, BYD is not the only Chinese company moving fast. After the press release, Zeekr also revealed a 1.2 MW charger.

Just Monday at its Tech Day (21.04), CATL announced >1MW charging speed with 12C peak power capabilities:

And just yesterday Huawei unveiled its 1.5MW charger claiming it is the industry's first fully liquid-cooled MW-class supercharging solution, although it seems targeted at trucks primarily.

Chinese companies seem to be in an arms race to the best fast-charging specs (the KPIs not always being very well-defined, but that’s another question).

Which begs a more general question : aren’t there drawbacks to this ultra-fast charging approach for cars?

The argument against ultra fast-charging

There’s mostly three arguments to be made against ultra-fast charging for cars:

Is it really needed?

What strain does it put on the battery?

What strain does it put on the grid?

Regarding market needs, some industry voices argue that 10–12 minutes is the real sweet spot as it’s the average duration of a highway stop, and that targeting 5 minutes charging is overkill.

It's true that even on highways, there’s usually really few cases where you need to refuel as fast as possible, it’s mostly a question of habit rather than concrete need. A 20-minutes break does not sound too bad, in most cases.

Regarding strain on the battery, BYD has patents on double cooling plates to improve heat transfer, signal modulation (e.g. pulses) to control heating from the BMS, and on the material side a range of patents on microstructured cathode materials. All this makes me think that they may be able to avoid major degradation modes in the battery, despite the high C-rates. Obviously, it’s still better to charge slowly, but ultra-fast charging once in a while should not destroy your battery (especially if the batteries manage to clear 1 million miles in ideal charging conditions).

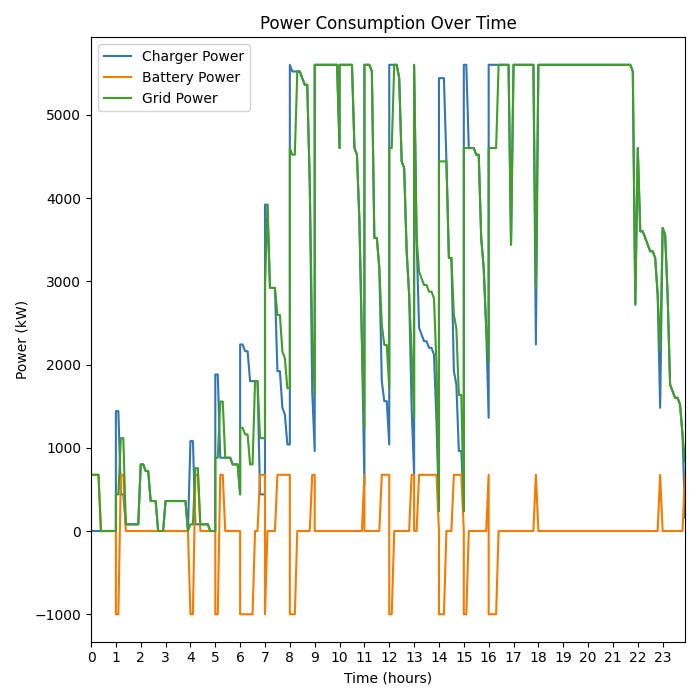

And finally regarding strain on the grid, I had some fun with a little toy model. I imagined a future highway station equipped with 3 different charger sizes and serving only electric vehicles.

I assume that the station processes 411 vehicles per day (with a bi-modal distribution visible on the next figure) and is equipped with 3 ultra-fast chargers (1MW), 5 high-power chargers (360kW) and 10 medium chargers (80kW). I assume every vehicle enters the station with around 20% charge left (batteries vary from 54kWh to 105kWh) and chooses a charger more or less at random but wants to charge in less than 30 minutes, preferably.

I assign vehicles to the chargers, compute the power at every time steps of 6 minutes, and stop when the battery is charged. The results are shown below. The red crosses represent the number of vehicles that entered the station over this hour, the coloured bars correspond to the different chargers:

We can see that the power peaks at 5.6MW, with pretty large 4MW swings in the span of an hour! For reference, the power profile of a town of 27k inhabitants in Jordan averages 200kW with 50kW hourly changes. And we’re only serving 411 vehicles, so you can imagine at the scale of a whole region leaving for holidays…

BYD does mention that they will add 225kWh stationary batteries to alleviate the peak load on the grid. Does it get rid of the problem? Let’s add these to the model. We can add a buffer battery that charges from the grid when demand is low and supports ultra-fast charging during high-demand periods. Here's what happens with a 675 kW / 675 kWh battery (or three 225kW/225kWh to support the three ultra-fast chargers):

The logic of the battery is simple: if the ultra-fast chargers are in use, the battery supports them until it’s empty or they’re no longer in use. If they’re not in use and the battery is not full, it charges from the grid. The grid power is then (charger power)-(battery power).

We can see that the battery gets discharged pretty fast during peak hours, and does not get any break to recharge. Indeed, 225 kWh is basically a bit over two Tang L (105 kWh batteries), so it’s not going to be enough when 20 vehicles enter the station per hour and the battery can’t recharge fast enough.

Let’s try doubling the size of the battery (1350kW/1350kWh) ?

There’s improvement, but the system still struggles when vehicle throughput is high. We can keep increasing the size of the battery, but then it becomes very much oversized 80% of the time, so it becomes a bit of a waste outside of peak hours.

If we remove the three ultra-fast chargers we do alleviate the load on the grid, although it is still significant:

The average waiting time per vehicle (including both charging and queuing), however, goes up significantly : from 20 minutes to 1h 10 minutes since many chargers are all busy at peak times. So we’re back to the initial premise of this article : charging time could become a major bottleneck on highways.

Now this is just a toy model, but it shows that matching refueling speed with electric charging is a big challenge. Not just on the battery technology, the vehicle design or the power electronics, but for the grid as well.

Conclusion

It should be underlined that the technical achievements from BYD are impressive : on the materials side to allow 8C charging rate, to the cell-to-pack design to improve pack-level energy and power density, to the power electronics design. As this piece notes, BYD’s press release made waves in the U.S., a market where it doesn’t even sell cars.

But I think it’s also important to remember that this kind of press releases is as much about brand image and tech milestones, as it is about delivering value to the end customer. Not that the grid problem is unmanageable, but it will be a while before our electric grid can sustain charging powers that are on par with refueling speed. Petrol is a very good energy carrier, after all.

High-power charging is not the only solution however, as we’ll see in part 2…

🌞 Thanks for reading!

📧 For tips, feedback, or inquiries - reach out

📣 For newsletter sponsorships - click here

Great Info...even though I don't understand 1/2 of it. But am learning - from the best source!

I'm a simple man. I see a post by Gaël and I like.