Welcome back to the DIY battery community with Román! In the first part he covered why people do DIY and the costs. This article will focus on the safety of these systems.

Safety

An essential aspect to consider, aside from cost, is safety. The primary difference between commercial and DIY battery packs is that the former must adhere to a range of certifications (UN 38.3, UL 2054, CE marking, IEC 62133, and RoHS) and undergo rigorous testing to ensure safety, proper performance, and environmental responsibility. DIY packs generally do not have to meet any legal criteria unless local safety laws require otherwise or selling and distribution are intended.

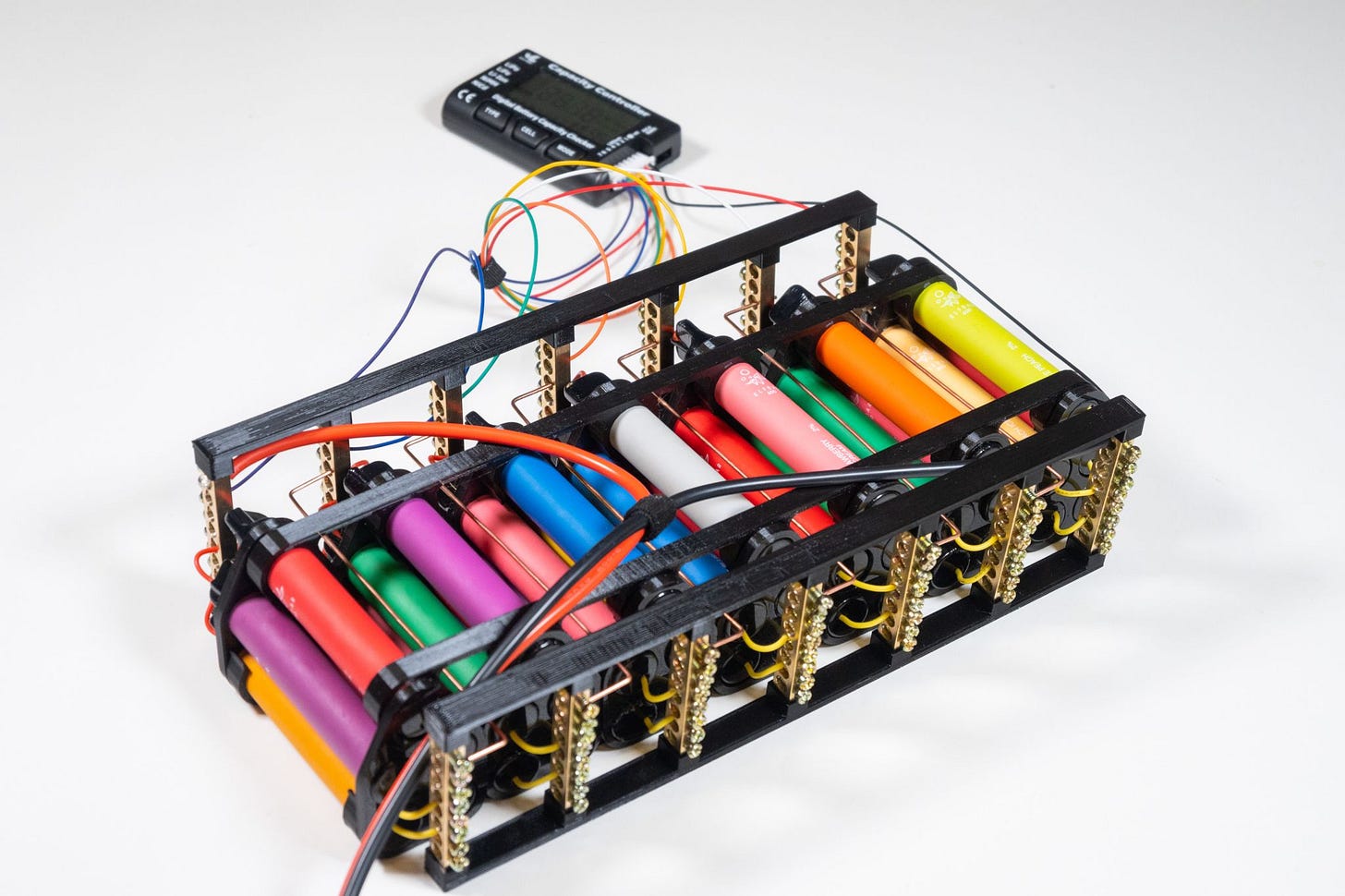

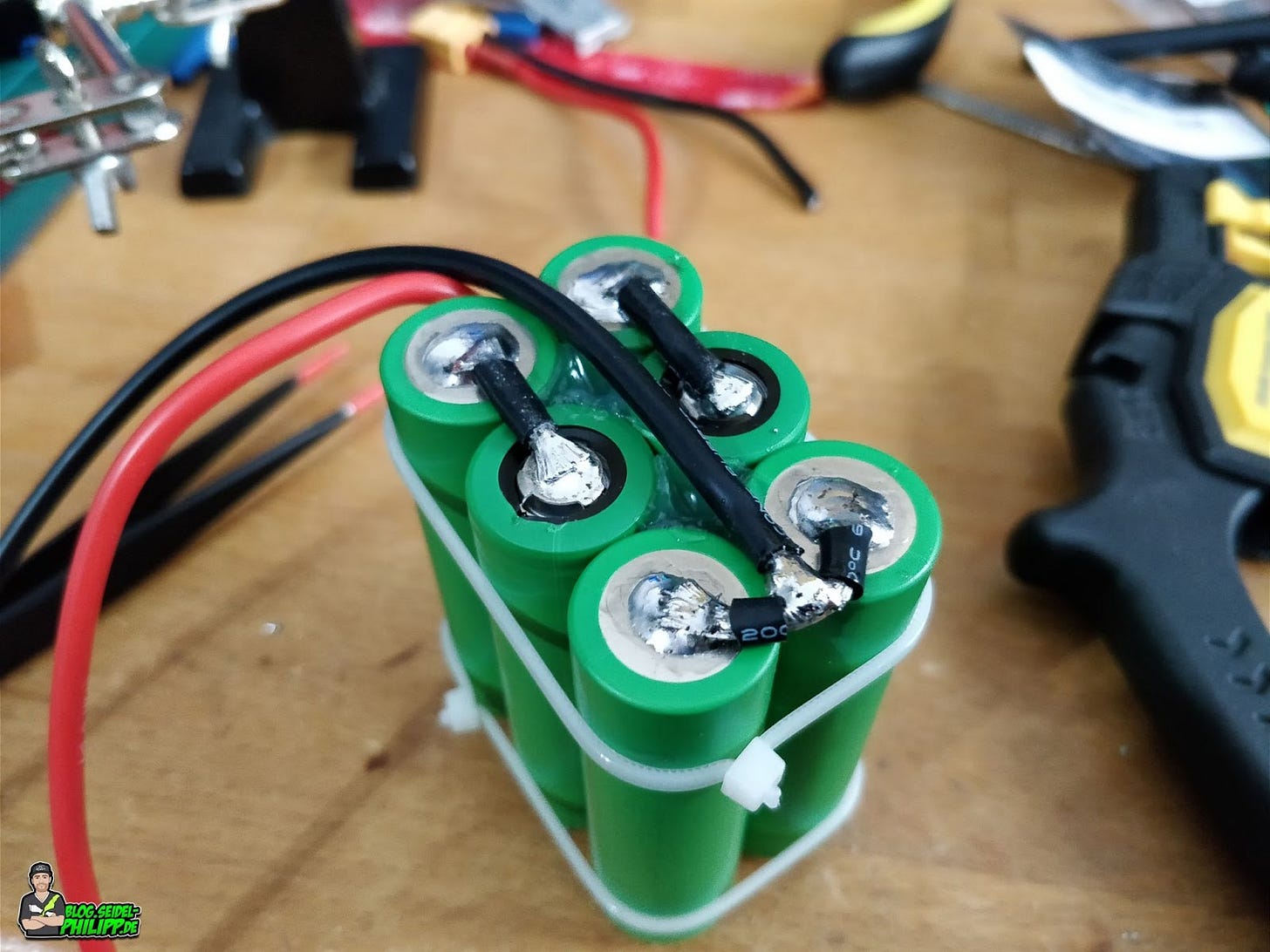

Although DIY battery packs are subject to fewer regulations, it is crucial to prioritize safety. This includes using high-quality cells, incorporating a BMS to prevent overcharging and overdischarging, ensuring proper insulation, and providing adequate ventilation.

If high-quality materials are used and safety is prioritized during assembly, DIY packs can perform as well as commercial packs and as safely. One could argue that because commercial packs are mass-produced, some issues may go unnoticed during production, while assembling a single DIY pack at a time allows for more focused attention, ensuring that safety precautions are carefully implemented, depending on the skills of the maker. To assemble safer battery packs it is better to begin with small ones and slowly upgrade to larger ones, hence ensuring a progressive improvement in general safety and performance.

Despite efforts to enhance battery pack safety, fire risks remain a significant concern. While comprehensive comparative data on DIY and manufactured battery packs is limited, e-bike fire incidents offer valuable insights into the potential dangers associated with both options.

The UK’s Office for Product Safety and Standards (OPSS) has published fire data collected from various fire and rescue services across the country for 2022 and 2023, along with more limited insights from 2017 to 2021. This data includes incidents involving both e-bikes and e-scooters. However, since no distinction is made regarding the origin of e-scooters, they will be omitted from this analysis.

Firstly, it is striking to note that e-bikes have accounted for a significantly higher percentage of reported fires compared to e-scooters. A substantial portion of these incidents involve converted e-bikes, referring to regular bicycles that have been transformed into e-bikes using conversion kits or fully DIY methods. These kits typically include a battery, motor, and other necessary equipment.

Charging battery cells or packs carries inherent risks, as overcharging can lead to thermal runaway, potentially causing explosions or fires. OPSS data from 2023 highlights that for both DIY and manufactured battery packs, above or close to 50% of reported fires occurred while charging. More importantly, among all reported fires, almost half of them occur while charging regardless of the build type.

The risk is particularly high for DIY battery packs, often due to low-quality components, faulty BMS, or improper charging procedures. A major concern in DIY arises from the battery cells themselves, as a user emphasizes: “My first advice is to not mix and match brands or different capacities of batteries together. This is EXTREMELY unsafe.” Mixing battery brands and capacities can disrupt the BMS, leading to decreased performance, uneven cycling, and, in the worst case, overcharging, which may trigger thermal runaway. For this reason, carefully selecting safe and compatible components is essential. As a rule of thumb, using cells of the same brand, type, and production date ensures optimal performance and safety.

While the data shows that DIY projects tend to be more faulty, resulting in more fire risks, it does not consider the component quality, the assembly procedure and its overall safety additions. Consequently, with an adequately installed BMS, well-matched high-quality cells, and safe charging practices, DIY battery packs can be as safe and reliable.

Final thoughts

When I started researching DIY and the reasons why people choose to build their own battery packs, I was surprised by the significant cost differences and the lack of affordable commercial options. DIY is not just about saving money, it also involves customization and tailoring to oneself needs.

At first, diving into such projects may seem intimidating, requiring both time and financial investment. However, in the long run if safety is adhered to, the benefits often outweigh the challenges. With the support of growing online communities and shared knowledge, learning has become much more accessible. Safety must remain a top priority. It is crucial to source high-quality components, ensure proper assembly, and understand the correct handling and maintenance of the battery.

🌞 Thanks for reading!

📧 For tips, feedback, or inquiries - reach out

📣 For newsletter sponsorships - click here

I honestly do not believe that we do the battery community a service by “encouraging” people to do their own DIY battery projects.

I appreciate the fact that you highlight the safety issues, but I think that is not stressed enough, especially in the conclusion part.

Batteries are safe, when they are handled, manufactured, design and put together into a product by professional which need to follow certain standards and follow testing requirements. This ensures that it works. Circumventing this will of course bring down the costs, but do you believe that is worth it?