This week we have a piece from Román. Román is a PhD student working on metal-sulfur batteries, passionate about battery and material science. He enjoys exploring battery projects beyond the lab, such as DIY. This two parter will cover DIY- why and costs in the first part, and safety in the second part.

DIY culture has seen a remarkable increase in recent years, driven by easier access to online resources, economic considerations, and a desire for hands-on creativity. According to The Farnsworth Group, 3 in 4 homeowners engage in some form of DIY home improvement and among all DIYers, Millennials lead in numbers.

Younger generations are more interested in sustainability projects as well as being conscious about their spending, so DIY projects have expanded from traditional to niche, such as battery projects. Social media platforms have seen a significant increase in tutorials and forums on how to assemble packs at home. This article will try to help readers understand the motivation behind such projects, as well as providing knowledge on the cost.

Why?

The biggest question that comes to mind is why people would choose to make their own battery packs. Some key reasons include the fact that commercial packs often do not meet customers' specific requirements, the difficulty of obtaining battery packs directly from manufacturers, and the lack of a business-to-consumer (B2C) approach, making manufacturers less flexible in adapting their products. Another reason is related to the cost, which will be explored later in the article.

When looking at commercially available battery packs, finding one that meets specific needs—especially for larger packs—is not always straightforward. A simple web search often does not provide suitable options. Also, purchasing directly from a manufacturer is usually not possible through their website, and when it is, the prices tend to be high. These challenges create a strong motivation for certain customers to start producing their own packs. This argument is supported by Reddit users who mention that “bigger capacity shifts things in favor of DIY”.

Economics behind DIY battery packs

Speaking with friends who build their own packs, the primary reason they turn to DIY is cost. This trend is also reflected in online forums, where DIY enthusiasts frequently share insights such as: "If you plan on building multiple packs, the cost drops by approximately 50% after the initial investment" or "I can build my packs for half the cost per kWh compared to off-the-shelf options."

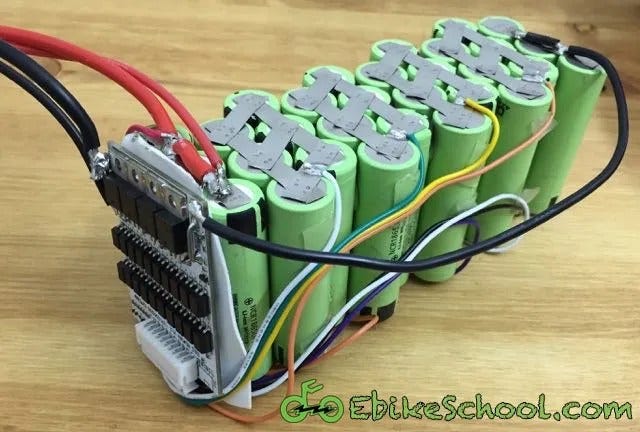

To understand the cost dynamics, it's essential to first examine the materials and tools required to build a battery pack. In terms of tools, it mainly requires a singular significant one-time investment: a spot welder. Among DIYers, the Malectrics spot welder is one of the most commonly recommended options, retailing at around 115 €. These instruments use electrical energy to heat up a spot where two metals are in contact, hence causing them to fuse together.

When it comes to pack components, key elements include a battery management system (BMS), wiring, connection points, insulating layer, and the battery cells themselves. The BMS typically costs between 40-50 €, with many modern options that include a built-in QR code linking to an app, allowing users to monitor battery data and detect potential issues.

Wiring is relatively easy to obtain, and its cost generally does not surpass 50 €, as noted in an e-bike subreddit where a user estimated "$30-50 for miscellaneous large-gauge wires." For connection points, nickel busbars are commonly used. These are widely available, often sold in bulk, and range in price from 0.50 € to 1.50 € per unit.

Regarding safety, it is important to consider the insulating layer, which is mainly composed of a PVC film, whose cost averages 3 €/meter. Additionally, Kapton tape or fish paper can be also added for extra insulation in some critical areas.

The most crucial and expensive component, however, is the battery cells. These have various configurations and specs, allowing DIYers to choose the most suitable option. Opposed to pre-assembled packs, individual cells are readily available both online and in physical stores. Retailers such as nkon.nl and akkuteile.de—popular resellers in Europe—offer cells for an average of 2 to 4€ each, with some as low as 1€/cell.

Interestingly, these suppliers also sell reclaimed batteries, some of which come from old electronics or primarily have welding defects. Resellers track the batteries and ensure they are functional, meaning these defects do not impact performance or safety. For example, nkon.nl provides the reason for each battery's reclamation, along with safety metrics that have been tested, such as internal and external damage, cell resistance, and whether it has been used before. Notably, these cells can cost as little as €0.50 per cell and are also a good way to give batteries a second life.

With the knowledge on prices, let’s break down the cost of assembling a battery pack for a standard e-bike. Assuming a 48V, 20Ah configuration (which equates to 960Wh, providing an estimated range of 80km), one could use a 13s6p setup—13 cells in series and 6 in parallel—totaling 78 cells (each of roughly 3 Ah).

Based on the above, purchasing these cells at an average cost of 2.4€/cell would amount to approximately 190€. Adding a 45€ BMS, 50€ for wiring, and around 20€ for nickel busbars (assuming 25 busbars: 13 for parallel connections and 12 for series connections), the total cost would be 305€. Including the 115€ spot welder, the overall investment reaches 420€.

However, costs can vary significantly depending on the choice of cells and pack configuration. As noted in the DIY Solar Power Forum, one user pointed out: "Also allows me to use larger cells, which are generally cheaper." This flexibility in customization enables DIYers to build battery packs at a significantly lower price than off-the-shelf alternatives.

Compared to available online options, the prices are similar or slightly higher. For example, on eBay, it would cost around 369€, while major retailers may charge up to 620€. This is where DIY has a clear advantage. As mentioned earlier, once multiple packs are made, the cost per unit decreases since fixed costs have already been covered. By opting for higher-capacity cells (such as 5 Ah), the configuration can shift to 13s4p, meaning only 52 cells will be required, potentially bringing the price to a range of 200-250€ after having paid the fixed costs. The overall cost can be significantly reduced.

What about the safety of these systems? Come back next week for part 2!

🌞 Thanks for reading!

📧 For tips, feedback, or inquiries - reach out

📣 For newsletter sponsorships - click here

Good information, don't forget RV & boating & off grid solar community are using prismatic LiFEPo4 cells that are inherently safe and reliable. 4 cells + BMS = solar storage battery. I elected DIY route since I could get 2X the capacity at lower price than commercially available LiFePo4 batteries. Solar storage does not need the discharge performance of cylindrical cells and are lower $.

Great info! Keep up the great work.

Bill from Canada