Charged Careers

a look at where battery experience can take you

Issy finished her PhD recently. Since she’s thinking about it a lot, we thought it would be useful to take some time to lay out the variety of paths where battery knowledge and experience can actually take you, especially for anyone (fresh grads?) who might be wondering which direction to explore next.

If you’re looking for your next move, it can feel like a bit of a minefield to look at the job market. Big players going under, small players raising money, AI shoved absolutely everywhere and the general economy feeling like it could upend at any minute. The good news is that despite it feeling desperate, the global demand for batteries is still growing, and there’s plenty of avenues where having some battery experience and knowledge is extremely valuable.

This article is going to set out the different segments of the battery job market under 4 subheadings: Materials, Cells, Use Cases & Recycling. I’m trying to directly relate jobs to batteries, so I’m sure there’s lots of other things that could also be possible that I don’t mention. This is not an exhaustive list, it’s an attempt to spark excitement if you’re feeling a bit lost or disillusioned that there are so many opportunities. Some of it is obvious, but I hope that something is helpful.

This is quite a Europe-centric view, since I live in Europe, but the same avenues of opportunity should apply in many places.

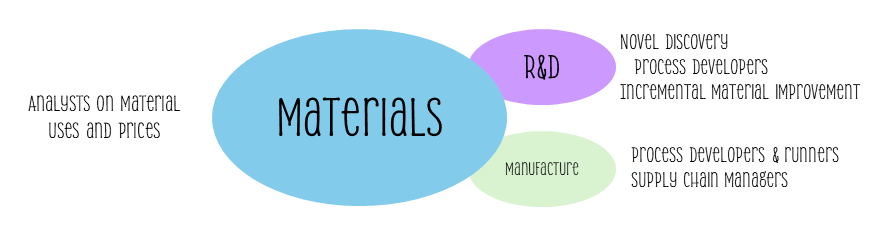

🪨 Materials

Materials for batteries can be anything from active material in electrodes to electrolyte mixes to casings. For companies like CATL who are vertically integrated, they will have most of this inhouse, but for many other companies they will buy in active material and other bits. I’m not discussing mining here because whilst batteries depend on it, experience with them doesn’t often directly interface with mining itself.

Research - Novel Discovery

Someone has to find new materials for everything from cathode, anode, electrolyte additive, separator etc etc, and look at the fundamentals of why they work or don’t.

Types of role: This is often in academia, or national research labs that have the time and resources to try lots of permutations, many of which won’t work. We are also seeing these processes sped up by machine learning which can help save on experiment time.

Places doing this: Academic institutions, National Labs. There are many machine learning/AI assisted software companies, we discussed them in depth a while back.

Development - Process & Incremental Material Improvement

Taking a material from ‘promising’ to ‘made at scale’ is no mean feat. Often, businesses are being created at the same time as at-scale synthesis is perfected. Then, when a product works, your competitors are always iterating. How can your product perform 5% better?

Types of role: Scale up engineers and general ‘fixers’, as well as instrument specialists and traditional ‘scientist’ roles.

Places doing this: eg. graphite companies mixing their product with silicon to give that extra performance boost. Instrument companies selling specific instruments.

Manufacture

You can make the product at scale, but now you have to do it consistently and deliver 100s to 1000s kg to customers. How do you secure your supply chain and keep the lights on?

Types of role: Everything that comes with running factories at scale - quality control, production engineers, equipment specialists, supply chain managers, plant technicians etc etc. Materials characterisation specialists.

Places doing this: So many places for each component.

Other relevant roles

It’s important to map material uses and prices across the battery industry. Gold and other precious metals have been tracked by commodity traders for decades, and now we have companies doing this for battery minerals.

Types of role: Analysts, traders, sales reps, consultants etc.

Places doing this: Benchmark Mineral Intelligence, CRU, Wood Mackenzie etc.

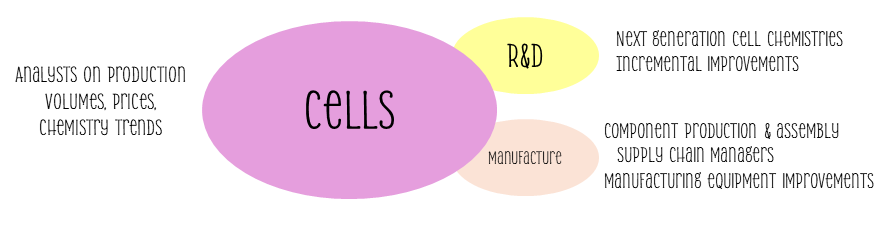

🔋 Making Cells

R&D

The next generation of cell chemistries needs developing somewhere. The exact right cell formulation has to be perfected in r&d. At the same time, there are incremental improvements to be made for existing cells, like new additives, that can be added to the exisiting manufacturing set up. Even the manufacturing set up itself can be improved, such as dry coating electrodes.

Types of role: Material scientists, etcetc.

Places doing this: Morrow Batteries with LMNO, Lyten with Li-S, Anaphite for dry coating.

Manufacture

Making cells at scale is difficult, and most of the industry is based in China. There are a few European examples and people making different scales.

Types of role: Again, everything that comes with running factories at scale - quality control, production engineers, equipment specialists, supply chain managers, plant technicians etc etc. Cell characterisation people in particular: electrochemical, chemical & mechanical, particularly around failure analysis.

Places doing this: ACC in France, soon CATL in Hungary. Formerly Northvolt, Tesla in Germany.

Other relevant roles

Similarly to the materials example, there are analysts & consultants watching the markets looking at volumes of cell production, prices, chemistry trends and all of that jazz.

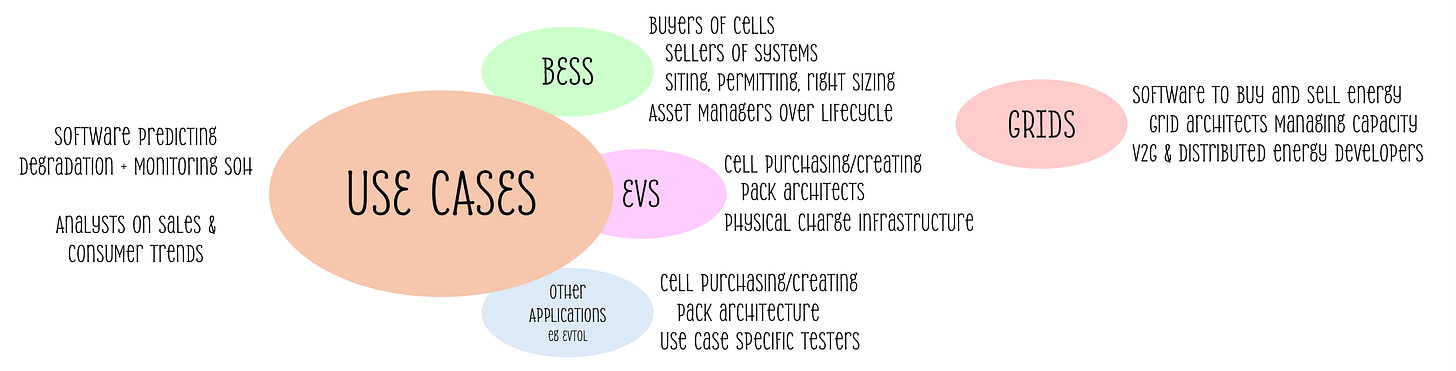

🚗 Use Cases

This is where it gets the most diverse when we start to deploy cells.

EVs

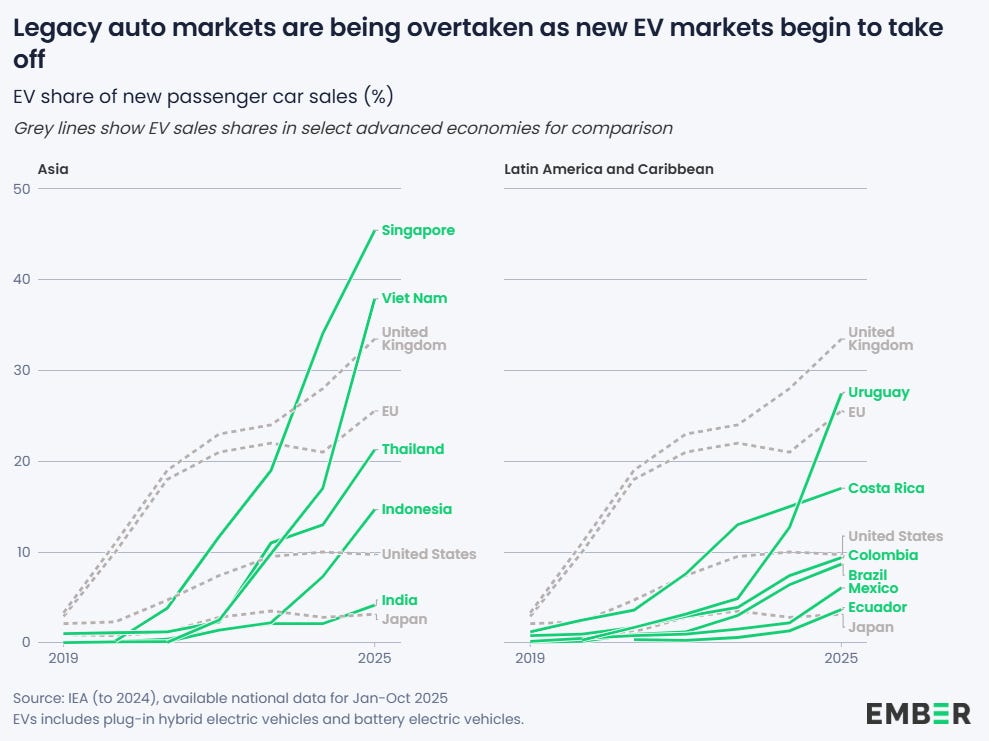

EV growth in Europe and the USA has slowed down a little, but EV growth worldwide is exploding as a key part of the energy transition. Some OEMs are making their own cells inhouse but many are buying them in, so need quality assurance and strong relationships with suppliers. Beyond the EVs themselves, there are also questions around charging infrastructure for longer journeys and integrating with urban achitecture.

Types of role: Cell buyers, pack engineers, installers and runners of charging infrastructure etc.

Places doing this: Basically all the European car manufacturers: BMW, Renault, Volvo, but don’t forget the newer market entries like BYD.

BESS

Similarly, in the UK the Battery Electric Stationary Storage (BESS) market grew last year by 45%. BESS is here to stay as a key balancing force in our energy systems. Building big battery systems is an engineering and logistics challenge, and then needs managing so the battery lifetime is as good as possible and it makes money. There are even places that do temporary BESS for events like festivals. BESS can also be used to take high electricity demand off the grid when necessary, for instance spreading the data centres or EV charging systems load so as to alleviate pressure at peak hours, and there are many software companies helping to manage battery assets in this way.

Types of role: Sales and buyers of cells and systems, siting, permitting, right sizing, developer, electrical engineer and much more. Energy traders who sell and buy electricity on the market either by day ahead or intra day.

Places doing this: Ingrid Capacity in Sweden, Decade Energy in France, Big Ass Battery in the Netherlands, Grid Faeries in the UK, for the trading price prediction side Electricity Maps in Denmark.

Relatedly: Grids

So the big batteries are installed and running well. Where should the next installations go? How do we get smart about using the batteries sat in people’s houses, people’s cars and generally making our grid resilient using batteries?

Types of role: Energy systems engineers, vehicle to grid developers, distributed energy modelling, virtual power plants. This is a massive space with loads of different role types, often but not exclusively in software.

Places doing this: National Energy Systems Operator (NESO) in UK, and many software companies helping managing charging stations and grid load.

Other applications

We’re talking trucks, EVTOLs, electric aircraft and even small electronics like smart watches. Each application has specific demand on battery pack and as such its own set of roles, and this space is pretty massive and diverse.

Types of role: Electrical engineers and pack specialists as well lots of application specialists.

Places doing this: Scania in Sweden, Vertical Aerospace in the UK, Fortescue in the UK/Australia.

Software & Modelling

Each battery application requires a battery management system (BMS) with sophisticated software architecture spanning multiple layers. Embedded engineers develop the low-level firmware in C that runs directly on the BMS hardware, managing real-time communication protocols between slave boards (monitoring individual cells), master boards (coordinating pack-level decisions), and cloud connectivity. They ensure reliable, deterministic performance under strict timing and memory constraints. In contrast, data analysts and scientists work in the cloud environment using Python and other high-level languages to process the massive volumes of telemetry data streaming from deployed battery systems. They build machine learning models to predict degradation patterns, optimize charging strategies, and detect anomalies across entire fleets.

Types of role: Software engineers and battery modellers, as well as lab scientists to gather data. Data scientists.

Places doing this: Elysia, About:Energy and Breathe Batteries in the UK, as well as many others. We covered this sector in depth back in 2024.

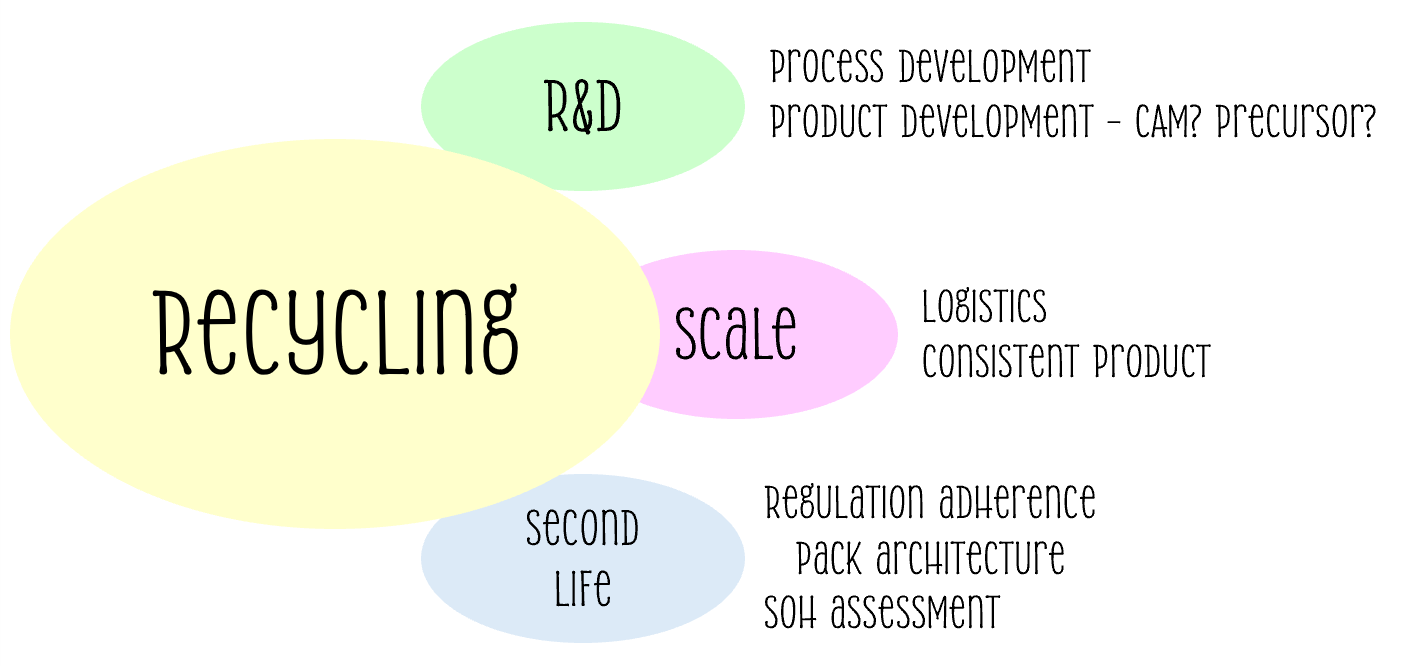

♻️ Recycling

The panacea of all our battery uses, I’ve separated recycling out from materials due to the logistics and challenge of getting material out of a car on someone’s drive and into a plant somewhere to be transformed back into a carbonate or hydroxide, as well as second life opportunities. However, a lot of the materials stuff here will overlap.

Research - Novel Process

Processing spent batteries into new starting material is full of both challenge and opportunity. The percentages of metal in the feedstock are much higher than you’d find in mining, which makes ‘urban mining’ a very high reward activity. However, the feedstock is inhomogeneous, meaning there is plenty of scope for making these processes more efficient, higher yield, and using less chemicals.

Types of role: This is often in academia, discovering the yield of a new process or new solvent etc. Discoveries are often spun out into companies or sold into existing places.

Places doing this: Academic institutions and often small start ups. Bigger companies will also often be doing their own in house research if they have the resources.

Development, then Scale

A new or even centuries old process of getting metal ions into the desired form has to happen at scale for it to be effective at recycling batteries. Then, these companies need to work out how to get batteries from car scrap yards to their plants and ship them safely.

Types of role: Scale up engineers and general ‘fixers’, as well as instrument specialists and traditional ‘scientist’ roles. At scale, this needs everyone from quality control, production engineers, equipment specialists, supply chain managers, plant technicians etc etc. Logistics managers, shredders and lots of policy compliance for these logistics.

Places doing this: In Europe, companies are ramping up from the process development scale to a larger scale. Tozero in Germany, Altilium in the UK etc. In China, CATL and others are already at massive scale.

Second Life

The range in your car has dropped below 80% of what it used to be, but now it can be used for something else. In reality, this is a real challenge and regulatory minefield. Still, there are people acing it! As well as used batteries, there are also unused surplus batteries sitting around in warehouses that come with spec sheets and need new home. These offer less of a challenge than used ones.

Types of role: Policy compliance, battery scientists who assess SOH for used cells, engineers to reassemble new packs.

Places doing this: Rebaba in Sweden and Cling Systems, also in Sweden.

Broader avenues

Start ups and bigger companies all have quite few roles in common which are also highly relevant to batteries:

Finance - venture capital and knowing where to put money to make impact, as well as grant writing for companies

Business development - making the right calls and connections to help the company make impact

Consulting - quite often companies don’t need a full time role in house, and will hire a consultant to cover a gap.

Sales - it’s important that knowledgeable people help customers get the right battery or product!

Sustainability - not only regulation compliance but impact on people and planet and mitigating things like waste too.

Safety - batteries are dangerous so ensuring that the risks are minimised.

Policy - these roles don’t tend to directly interface with batteries but the decisions made on this level affect every other role in this article. Many businesses make a huge effort to interact with policymakers for this reason.

I hope this fairly comprehensive overview of battery careers was a bit helpful or thought provoking. Good luck 🍀

🌞 Thanks for reading!

📧 For tips, feedback, or inquiries - reach out

📣 For newsletter sponsorships - click here