A short brainstorm on niobium

It’s nice to pause and take stock of materials. This week we’re diving into Niobium - a lesser talked about battery mineral, not quite of lithium or cobalt rockstar fame. However, it’s earned its place for a couple of reasons.

And speaking of materials, one important phenomena to evaluate is thermal runaway which can quickly lead to catastrophic battery failure and critical safety risks. It can occur when electrode materials undergo exothermic reactions that cause rising temperatures and accelerated reaction kinetics. Research shows that the state-of-charge of a battery can impact the onset temperature, mechanism, and energy release of reactions.

How can you analyze and mitigate the risk of thermal runaway? Differential scanning calorimetry (DSC) can be used to measure the heat flow of electrode materials. Scanning across a range of temperatures allows detection of exothermic reactions that may lead to thermal runaway. The impact of state of charge SOC of materials on the onset temperature and amount of energy released can be measured, making differential scanning calorimetry a useful tool in battery safety evaluation.

TA Instruments is the leader in analytical instrumentation and offers resources to help battery developers - see how isothermal microcalorimetry supports cutting-edge battery development in this blog, explaining five published cases of IMC in battery research.

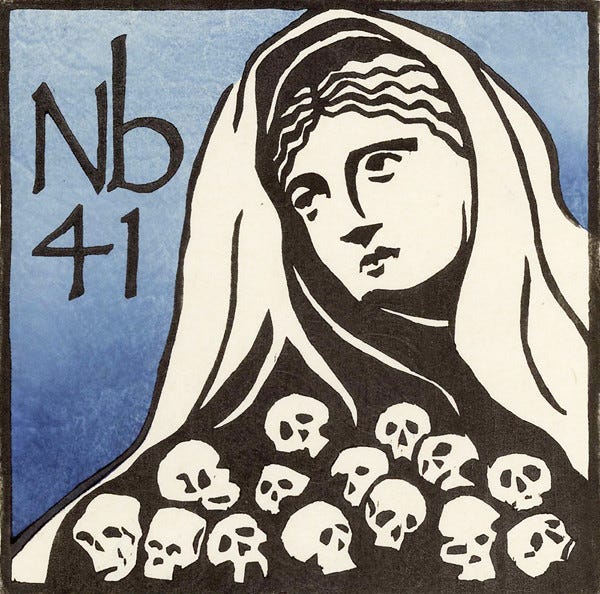

An intro to niobium

Niobium, named after Niobe, the daughter of Tantalus from Greek mythology, traces back to its discovery in 1801 by the English chemist Charles Hatchett. This gray ductile metal, found in pyrochlore and columbite, has a high melting point, impressive strength, and unique ability to superconduct at cryogenic temperatures, and can also help batteries with durability and fast charging. Today, 90% of niobium goes to steelmaking, and a small % to batteries.